Epe Foam U-Section

Epe Foam U-Section Specification

- Material

- Other

- Product Style

- Plain

- Characteristics

- Light in Weight, Waterproof, Odorless, Tear-Resistant

- Application

- Industrial Supplies

- Color

- White

- Packaging

- Customized, Rolls

- Size

- As required

- Pattern

- Plain

Epe Foam U-Section Trade Information

- Minimum Order Quantity

- 10 Rolls

- Supply Ability

- 100 Rolls Per Day

- Delivery Time

- 5 Days

About Epe Foam U-Section

Specification

|

Color |

White |

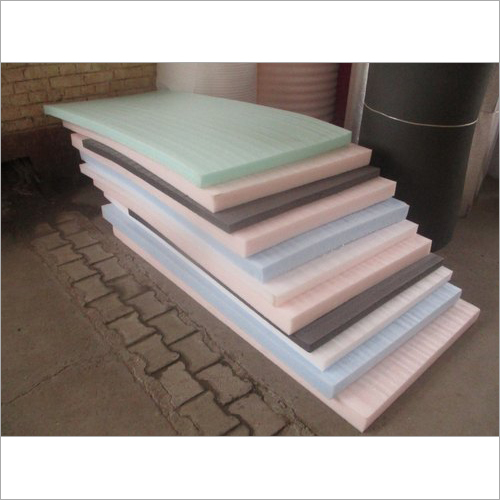

Owing to our rich knowledge as well as professional workforce, we have achieved a noted position as a reliable manufacturer and supplier ofEPE Rolls. These rolls are suitable for using in box liners, crate liners, protective pads, corner pads, partition lining, foam tapes & gaskets, heavy industrial machinery packaging and more. Offered rolls are made of closed-cell cross-linked polyolefin foam that controls condensation, has high thermal efficiency and sound absorption.EPE Rollsare available in different thickness and colors as per clients requirements.

Features:

- Very low water vapor permeance

- Water tight due to the pre-applied alupet foil

- High thermal efficiency

Versatile Packaging Solution

EPE Foam U-Section is designed to provide exceptional protection for a wide range of industrial products. Suitable for both delicate and heavy-duty items, these sections safeguard your goods from impact, moisture, and abrasion during handling and transport. Their adaptability allows customization for various dimensions and packaging needs.

Lightweight and Durable Material

Our EPE Foam U-Sections offer the advantage of being both lightweight and robust. This reduces shipping costs without compromising on the safety of your packaged materials. The tear-resistant and waterproof properties further enhance product longevity and performance under challenging conditions.

FAQs of Epe Foam U-Section:

Q: How is the EPE Foam U-Section used in industrial applications?

A: The EPE Foam U-Section is primarily used to cushion and protect industrial supplies, such as pipes, rods, or fragile components, by providing a secure barrier against shocks, moisture, and abrasions during transport or storage.Q: What are the key benefits of choosing EPE Foam U-Sections for packaging?

A: EPE Foam U-Sections offer multiple benefits, including being lightweight for reduced shipping weight, waterproof to prevent moisture damage, tear-resistant for durability, odorless for product safety, and fully customizable to match different size and shape requirements.Q: When should I opt for custom-sized EPE Foam U-Section rolls?

A: Custom sizes are recommended when your products or components have unique dimensions or require specific coverage to ensure a snug fit, maximizing the protective qualities and minimizing material waste.Q: Where can I source EPE Foam U-Section packaging in India?

A: As a manufacturer and supplier based in India, we offer nationwide distribution of EPE Foam U-Section packaging. You can contact us directly to discuss requirements and place orders tailored to your industrial needs.Q: What is the manufacturing process of EPE Foam U-Section?

A: The manufacturing process involves extrusion of expanded polyethylene (EPE) material, which is then shaped into U-sections and cut or rolled according to the desired size and specifications. Quality checks ensure each batch meets tear-resistance, waterproofing, and odorless standards.Q: How should EPE Foam U-Sections be stored before use?

A: These foam sections should be kept in a clean, dry area away from direct sunlight and chemicals to preserve their structure and effectiveness until needed for packaging applications.Q: What makes EPE Foam U-Section packaging a preferred choice over other materials?

A: Compared to traditional packaging materials, EPE Foam U-Section is favored due to its superior protective qualities, flexibility in sizing, eco-friendly properties, and cost-effectiveness for industrial packaging requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Epe Foam Sheet Category

Epe Foam L-Section

Price Range 2500.00 - 5000.00 INR / Roll

Minimum Order Quantity : 10 Rolls

Application : Other, Edge Protection for Glass, Furniture, Electronics, Sensitive Items during Transit

Packaging : Other, Bundled/Carton Packing

Size : 30x30 mm, 40x40 mm, 50x50 mm or Customized

Texture : Other, Smooth, Soft

Epe Foam C-Section

Price Range 2500.00 - 5000.00 INR / Roll

Minimum Order Quantity : 10 Rolls

Application : Industrial Supplies

Packaging : Customized

Size : As required

Texture : Smooth Texture

Expanded Polyethylene Foam Sheet For Packaging

Price Range 2500.00 - 5000.00 INR / Roll

Minimum Order Quantity : 10 Rolls

Application : Industrial Supplies, Packaging Supplies

Packaging : Customized

Size : As required

Texture : Plain

Epe Foam Rod

Price Range 2500.00 - 5000.00 INR / Roll

Minimum Order Quantity : 10 Rolls

Application : Industrial Supplies, Packaging Supplies

Packaging : Customized

Size : As required

Texture : Sponge

|

NARENDRA FLEXI PACK CO. PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry